Collection Logistics

Come behind the scenes at Powerhouse Castle Hill and meet some of the people managing the logistics of the Powerhouse Collection.

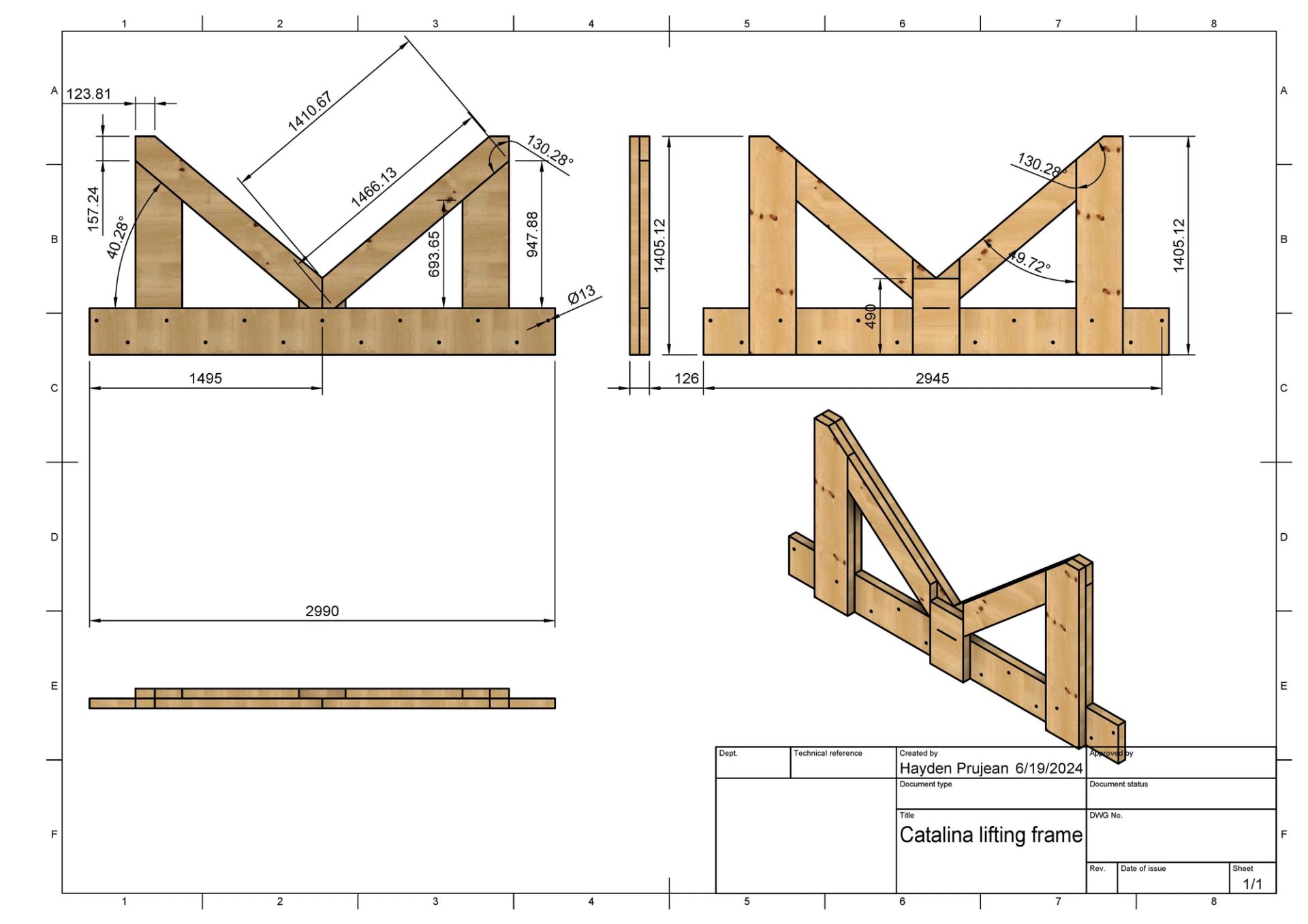

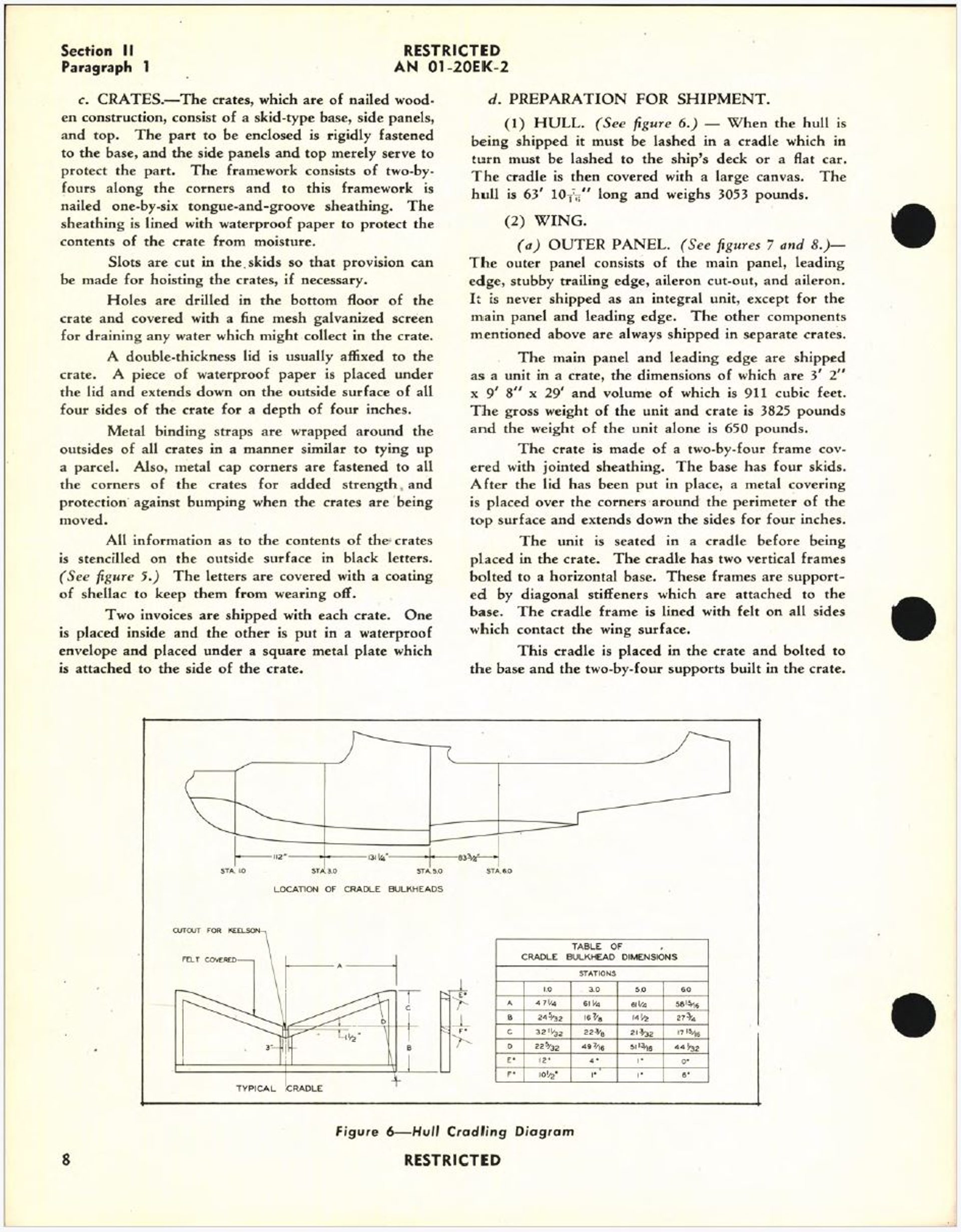

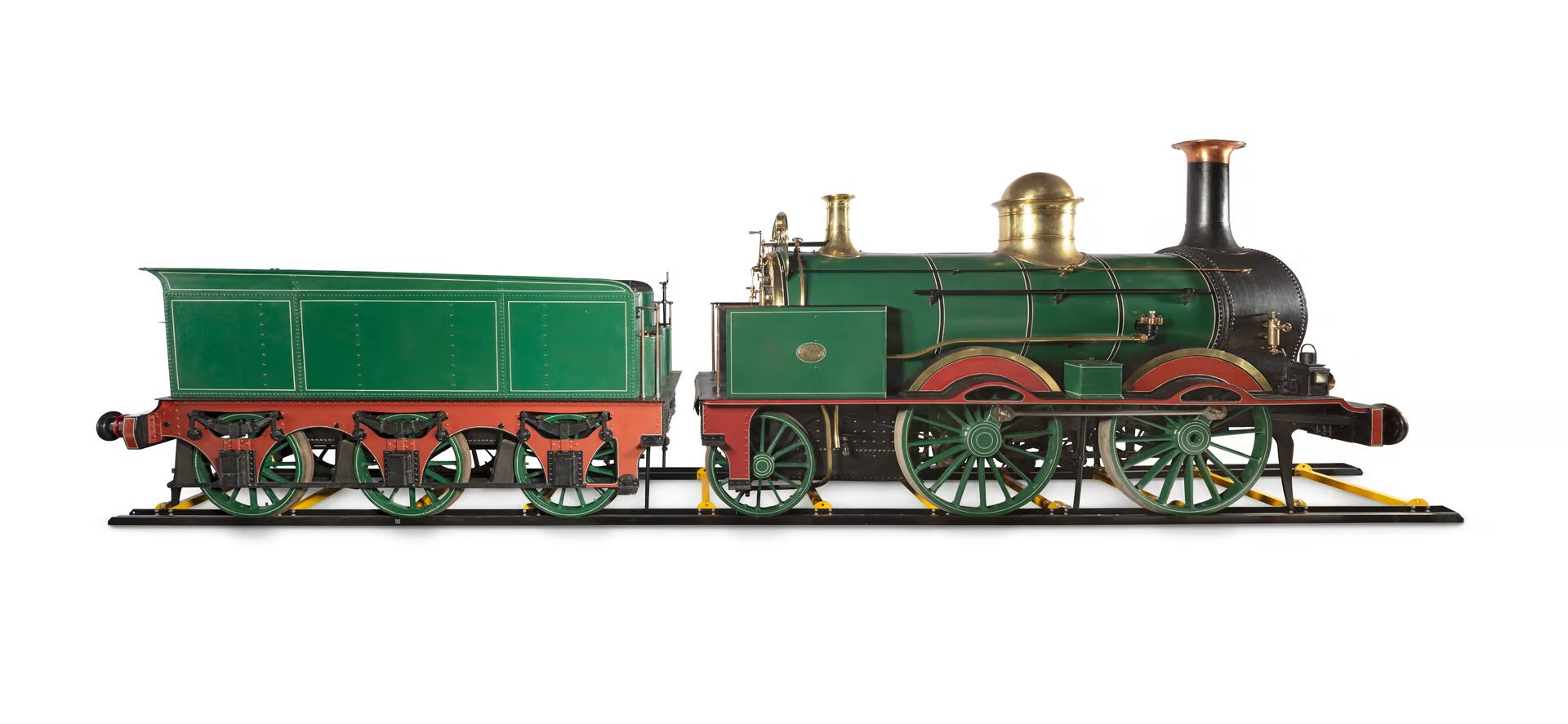

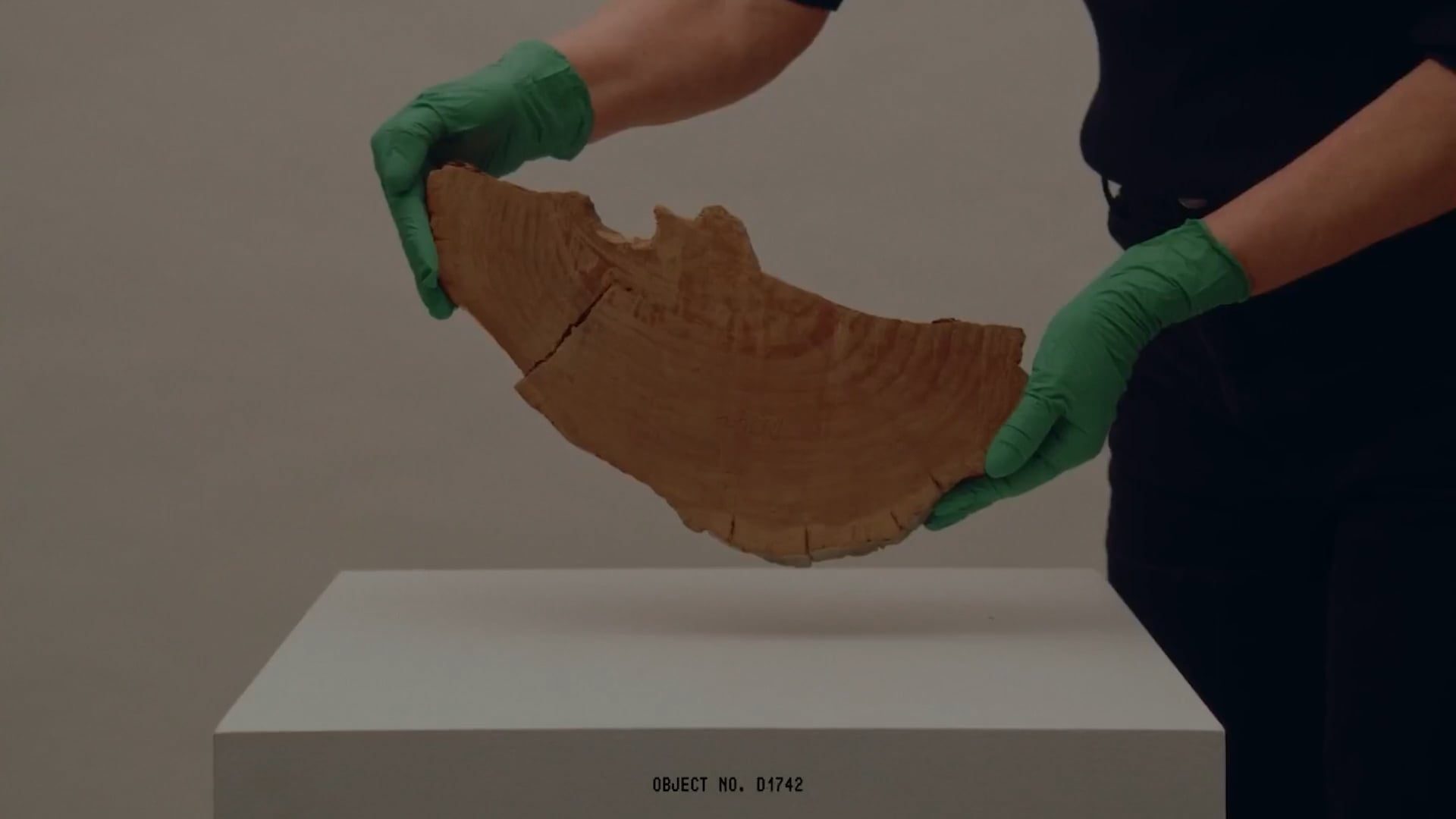

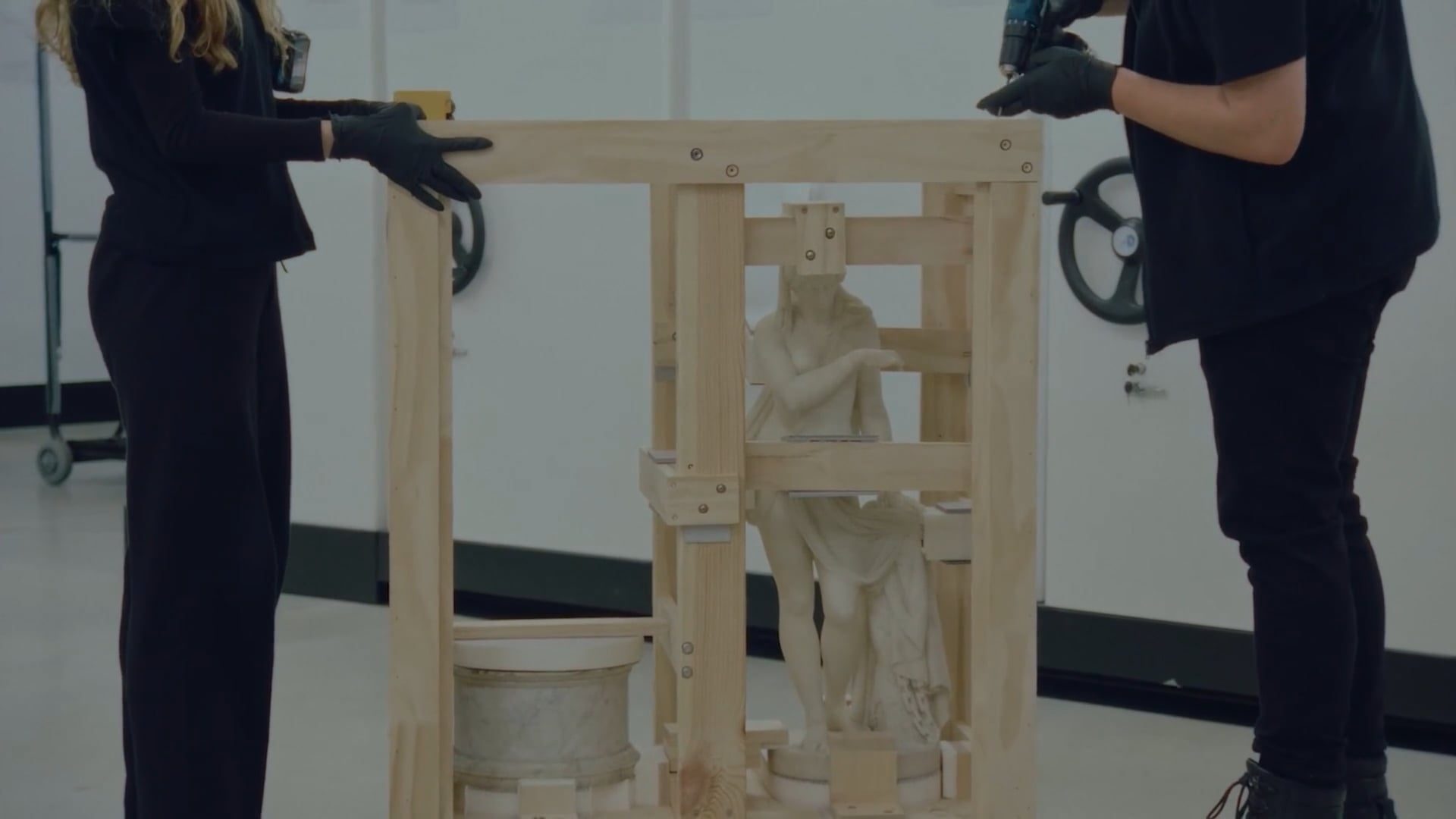

The Collection Logistics team is responsible for the meticulous planning, handling, packing and transportation of collection objects. Activities include the installation and deinstallation of museum exhibitions and relocating complex objects within and between collection stores. Recent projects include the disassembly, packing and relocation of the 70+ large and complex objects from Powerhouse Ultimo including Catalina Flying Boat Frigate Bird II, Locomotive No. 1 and most recently the Boulton and Watt rotative steam engine. Future projects will include the handling, packing, transportation and installation of complex collection objects into the inaugural exhibitions at Powerhouse Parramatta.

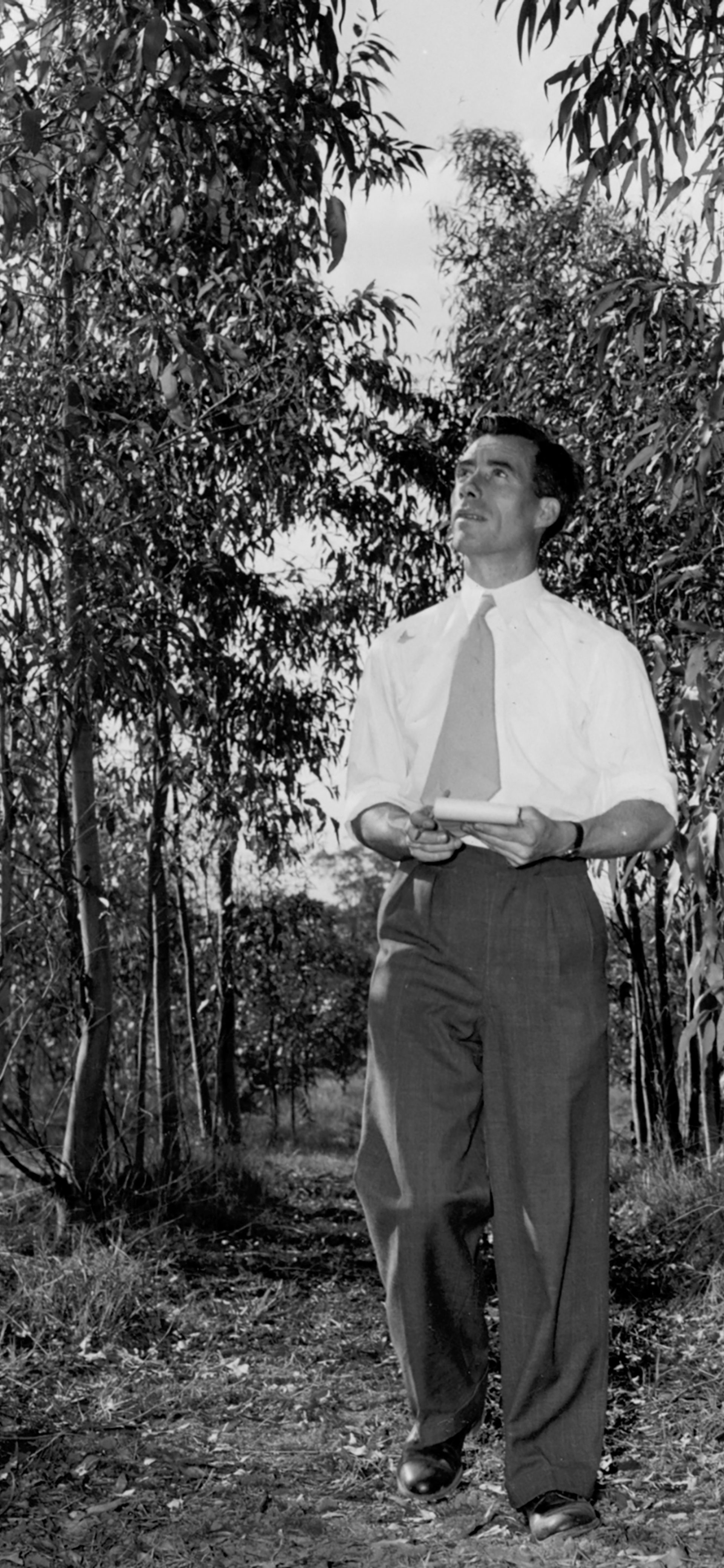

Charm Watts

Manager, Collection Logistics, Collections Project

‘The diversity of the collection is the reason I’ve always wanted to work at Powerhouse. I come from an industrial design background: I’ve taught design and technology; I’ve operated a furniture design and manufacturing business; I’ve worked in the contemporary art world overseeing installation teams and as an exhibition manager and collection relocation manager with Museums Victoria. So when I was recruited for the Powerhouse collection relocation project, I knew the role would be super exciting and engaging. Logistically it had components I’m familiar with, like designing and fitting out collection stores.

The difference with the Powerhouse Collection is the physical size of some of the objects and the variety of collection stores. I have a fairly in-depth understanding of the requirements of designing furniture, so I was able to marry that with 20 years’ experience in collection management practices to inform what was needed at Castle Hill for Building J. The principal behind the packing approach was to keep them safe by reducing the need for people to put fingers and hands directly on objects. Each object has a board, box, shelf or frame that supports it and provides shock absorption, so your fingers go on that handling aid instead.'